Written By Steven Ashby, Ph.D., PNNL

“It’s hot out there.” Those four words sum up many of our conversations this summer as we endured triple-digit temperatures and sought ways to beat the heat.

At the Department of Energy’s Pacific Northwest National Laboratory, researchers are working on technologies to help keep us cool, including two related to air-conditioning. While we rely on air-conditioning to make us more comfortable, it also is a significant component of our nation’s energy consumption.

In 2020, cooling the interior of residential and commercial buildings accounted for about 10 percent of the United States’ total energy usage. The technologies developed by PNNL are helping make those air-conditioning systems more efficient, reducing energy use and lowering costs.

First is a novel, energy-efficient dehumidification system that has been licensed to Montana Technologies for commercialization. Dehumidification is important because air-conditioning units work harder to cool humid air than they do dry air.

PNNL’s patent-pending dehumidification system requires up to 30 percent less energy and is one-third the size and weight of conventional dehumidifiers – a breakthrough that makes dehumidification practical and affordable.

When cooling humid air, air-conditioners condense water vapor in the air to liquid water. This process generates heat and can double the energy needed to keep things cool. PNNL’s technology, on the other hand, eliminates this condensation.

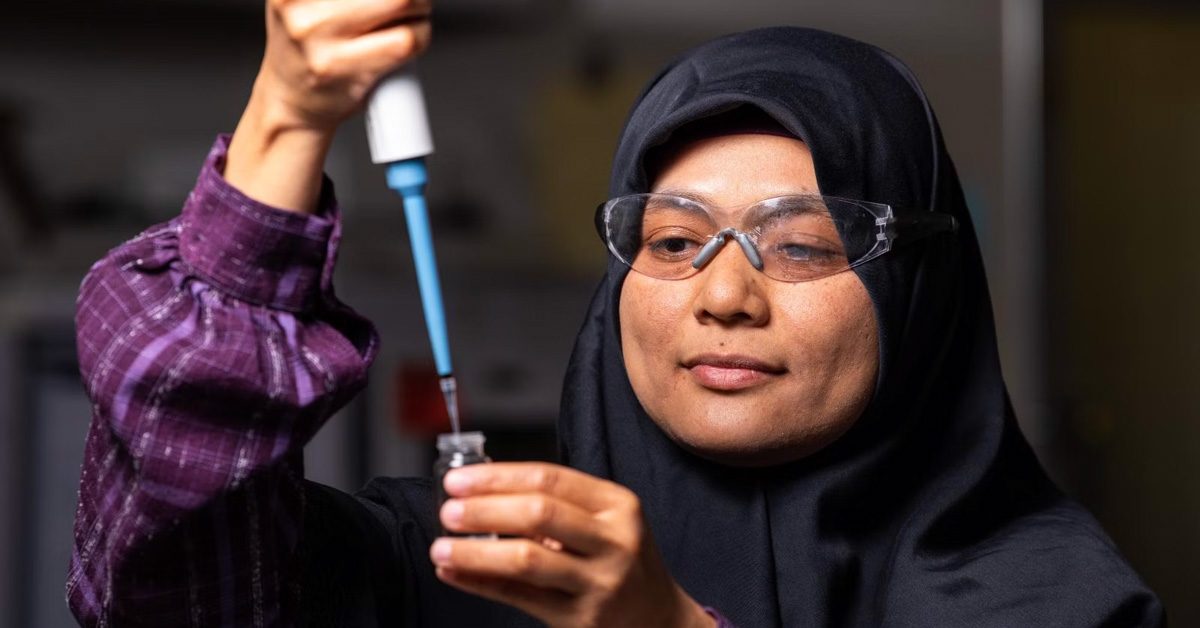

Known as AirJoule, the system uses advanced materials called desiccants to remove excess water from the air. It also captures the energy produced by water vapor adsorption to help recharge the desiccant for reuse. This self-regeneration technology enables dramatic reductions in energy use and system size. AirJoule can be easily integrated with standard air handler units and ducting, making it ideal for retrofits and new construction.

While promising for building applications, Montana Technologies initially plans to pursue the use of AirJoule in electric vehicles. Integrating our technology into electric buses, for example, can reduce the air-conditioning unit’s drain on the battery enough to extend the driving range by up to 75 percent.

PNNL researchers are advancing this same technology so water and carbon dioxide can be captured directly from the air in a single pass. The captured CO2 can be converted into fuels or stored permanently underground. The fresh water could support the needs of the local community.

Working with industry, our team will design, manufacture and field test this hybrid direct air capture system to help quantify how it supports the nation’s clean energy and climate change objectives.

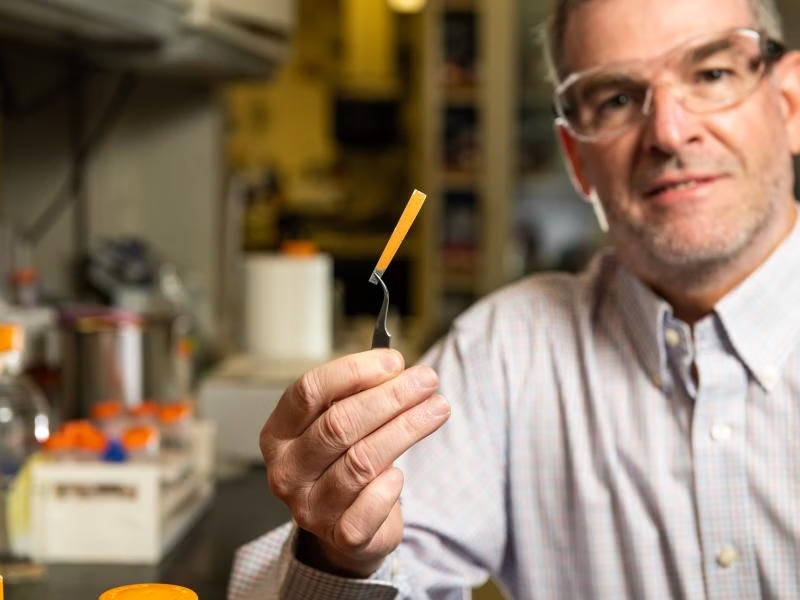

In a second project, PNNL materials scientists are collaborating with a commercial company to develop and test a technology that detects fluorocarbon refrigerant leaks from heating, ventilation and air-conditioning systems – a problem that leads to costly reductions in efficiency, poses health risks and can harm the environment.

The key technology here is a specially designed coating that selectively collects refrigerant vapor molecules. This gas-sensing film is deposited on the surface of a sensor that can monitor how acoustic waves shift as more gas molecules attach to the film.

Researchers experimented with prospective materials, explored methods for depositing it onto the sensor and built a prototype that is compact, inexpensive and highly sensitive. After lab tests, our collaborator, Parker-Hannifin, will evaluate the sensor’s performance in field tests.

By changing the sensing film, this technology can also be applicable to gases such as methane, ammonia and other vapor molecules of interest.

With August just around the corner, summer isn’t done with us yet. While it may be hot, remember that researchers at PNNL are putting their cool ideas to work so that our air-conditioners run more efficiently, and we can beat the heat without breaking the bank or harming the planet.